Low voltage IEC motors

MEPS

mandates transition of most low-voltage motors to higher efficiency class.

The change will reduce energy costs and benefit the environment.

As of July

1, 2023, a series of EU regulations known as MEPS came into effect. These

regulations concern low-voltage motors, which are now required to transition to

the higher efficiency class IE4, significantly more energy-efficient.

Compliance with these laws and directives is expected to lead to substantial

energy cost savings and have a positive environmental impact. The MEPS (Minimum

Energy Performance Standards) group of laws and directives for low-voltage

motors has been in development within the European Union since 2009.

For most motor power ranges between 0.75 kW and 1 MW, the mandatory efficiency class IE3 was previously required. Due to the MEPS package, manufacturers must now adopt the higher IE4 standard, characterized by lower electricity consumption. This applies not only to European manufacturers but also to those supplying products to the European market from Asia, the Americas, or Australia and Oceania.

"Core segment" under pressure from new rules

The new requirements affect the so-called "core segment" – motors

with power ranges of 75–200 kW, 2-pole, 4-pole, and 6-pole. This includes

configurations already covered by previous steps, except for Ex and brake

motors.

The directive also considers motors operated with frequency drives, which may

complicate the market situation. Consumers should be cautious of competitive

practices resulting in "special" motors for frequency drives

appearing on the market. These differ from standard DOL motors only by modified

nameplate descriptions and often fail to meet even the original 2011

requirements.

An exception until mid-2019 applies to replacement motors. Users may install motors identical to the original in clearly specified equipment (e.g., compressors), without the obligation to comply with the latest directive version.

In many respects, the new MEPS regulations help countries meet goals related to improving energy efficiency and reducing CO₂ emissions. The increase in motor efficiency in EU and EEA countries since 2011 can be attributed to ongoing work on this EU legislation.

ABB also offers the future-ready IE5 class

We teach our customers how to generate energy savings. ABB motors are designed

to meet not only local MEPS requirements but also international IEC standards.

We offer standard induction motors in a wide power range from 2.2 kW to 1 MW.

Customers can also purchase products from the future efficiency class IE5,

based on the advanced synchronous reluctance motor concept.

ABB also enables customers to calculate their own savings using various energy-saving calculators.

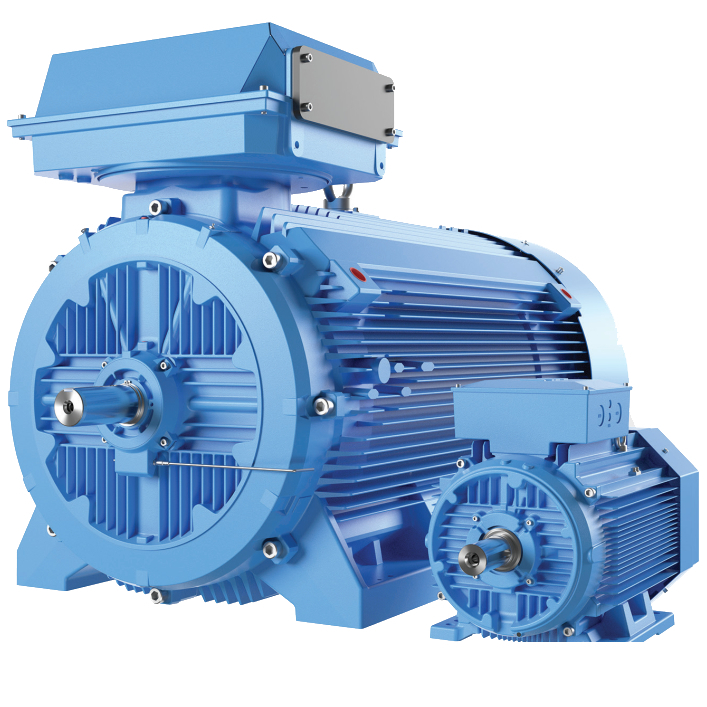

M3BP – Cast Iron Process Performance Motors

High-performance industrial motors designed for reliability and efficiency.

Process performance motors offer great flexibility for customer-specific

solutions and can be individually designed to meet precise application

requirements.

Various technologies are needed to ensure the best high-efficiency motor

solution across the entire low-voltage motor power range. ABB motors are always

fit for purpose, providing the most cost-effective and sustainable solution

based on your requirements.

Experience high-performance industrial motors built with precision to deliver

optimal performance for your operational needs.

Improve operational efficiency with our energy-saving motors, designed to

reduce your carbon footprint and support a sustainable future.

Efficiency classes from IE2 to IE5.

High-performance motors offer optimal solutions for applications where size and weight matter.

ABB has enhanced its high-performance aluminum IE3 motors with "Process Performance" certification.

The product complements standard Cenelec motors and uses smaller frame sizes than Cenelec designs for the same output.

These motors are especially suitable for applications with limited space and/or where more powerful motors are needed in smaller frames.

High-performance motors are an attractive alternative to conventional Cenelec motors, offering a compact, lightweight, unique, and cost-competitive solution.

Robust, reliable, and customizable, with fast availability, reaching efficiency class up to IE4.

ABB general-purpose induction motors are designed to the highest standards to deliver excellent reliability and efficiency.

These high-quality motors are ideal for sectors such as water and wastewater, HVAC, agriculture, marine, and general machinery.They are also perfect for OEMs integrating them into various applications such as compressors, pumps, and fans.

Our cast iron motors offer exceptional durability, efficiency, and performance for demanding industrial environments.

These powerful motors are built with cast iron construction to withstand mechanical stress, corrosion, and harsh conditions.

Available in efficiency classes IE2, IE3, and IE4, they optimize energy consumption while reducing vibration and noise for greater reliability.

M3AL

/ M3BL – Synchronous Reluctance Motors

Looking for top-tier motor solutions that optimize energy efficiency and

performance in industrial processes?

Look no further than ABB's IE5 synchronous reluctance motor series.

With advanced technology and engineering expertise, ABB delivers reliable and

high-performance motors designed to meet the demands of modern industries.

ABB synchronous reluctance motors are specifically designed to provide

ultra-premium energy efficiency (IE5), reduce operating costs, and minimize

environmental impact.

Experience exceptional performance with these motors, featuring high torque and

remarkable power density, enabling increased productivity in your operations.

ABB synchronous reluctance motors are built to withstand demanding industrial

environments, ensuring long-term performance and minimal downtime.

They offer versatile solutions for a wide range of applications.